Electrolyzer Scale and Key Technical Differences

Understanding Electrolyzer Size and Hydrogen Production Capacity

The size of an electrolyzer has a direct impact on how much hydrogen it can produce. We're talking about everything from small 1 kW models that generate under half a kilogram per day right up to massive gigawatt scale installations capable of making over 50 tons each day. When looking at smaller units, they tend to focus on taking up less space and responding quickly to changes. Industrial grade systems are all about getting as much output as possible though. Take for example a typical 10 MW alkaline electrolyzer which runs around 40 to 60 percent efficient and makes approximately 4,500 kilograms daily. Compare that to similar sized PEM systems which actually hit efficiencies between 60 and 80 percent but come with significantly higher upfront costs. This whole range shows why matching hydrogen production capabilities to available energy sources and what people actually need becomes so critical in practice.

System Efficiency, Scalability, and Degradation Across Scales

Different technologies handle scaling in very different ways. Take PEM electrolyzers for instance they keep pretty good efficiency around 70 to 80 percent even when running at partial capacity, which makes them great partners for renewable energy sources that come and go. The downside? They rely on those expensive platinum group catalysts, and over time these degrade pretty quickly about 2 to 4 percent efficiency loss each year. Alkaline systems tell a different story. Their efficiency is lower somewhere between 60 and 70 percent but what they lack in performance they make up for in cost savings. Materials are cheaper here, and degradation happens much more slowly less than 1 percent annually, which explains why we see them deployed at larger scales across the industry. Then there's modular solid oxide electrolyzers (SOE) that can hit impressive efficiencies of up to 85 percent. Problem is they need constant high temperatures between 700 and 850 degrees Celsius, which creates serious limitations both operationally and commercially speaking. Most companies find this requirement too restrictive for widespread adoption right now.

Modularity and Design Flexibility in Large vs Small Systems

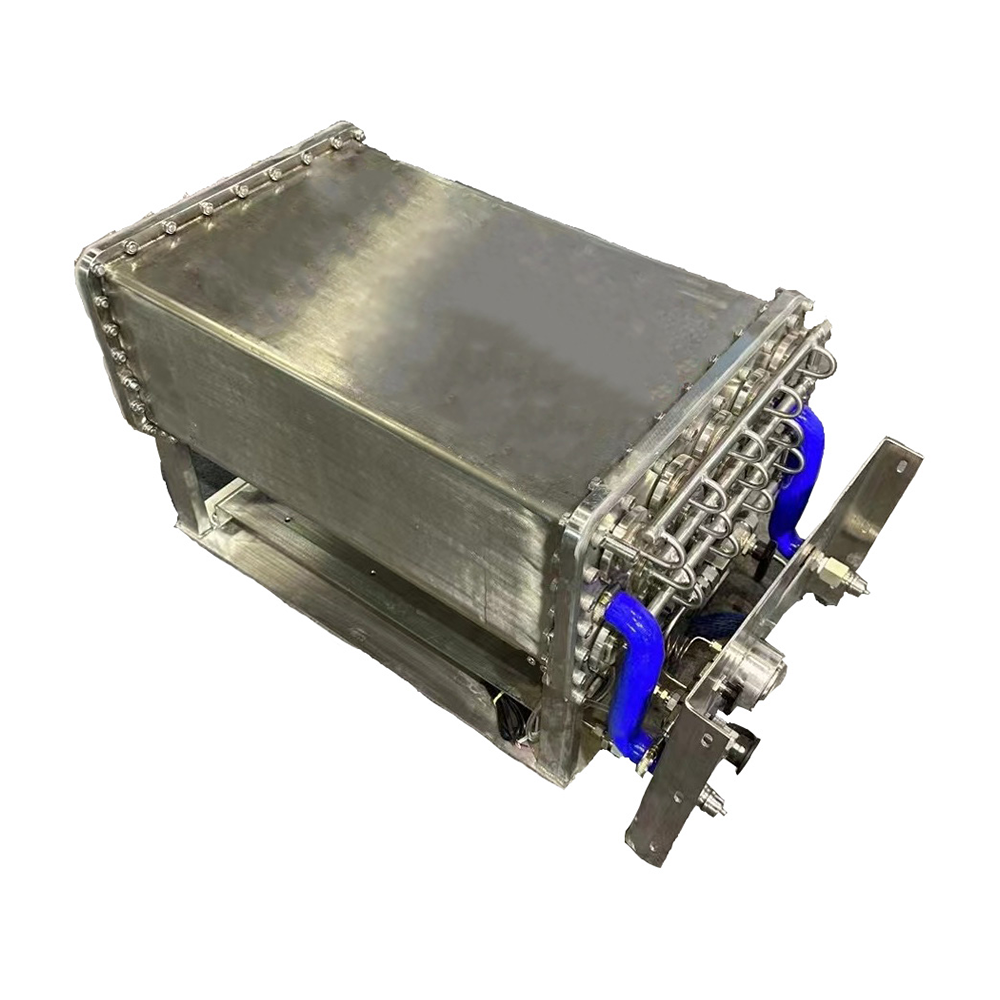

Alkaline electrolyzers tend to be the go-to choice for big central plants because their standard design cuts down on upfront costs by around 30%. On the flip side, PEM and AEM systems offer something different altogether. These modular setups work great for decentralized production needs. We're talking everything from small 500 kW containers right up to massive multi-megawatt installations mounted on skids. What makes these systems stand out is how they can scale up or down in 100 kW steps. For certain sectors like ammonia manufacturing, this flexibility really matters since demand swings seasonally by about plus or minus 25%. That kind of adaptability just isn't possible with traditional fixed-size equipment.

Comparing Electrolyzer Technologies and Their Scalability

Overview of PEM, AEL, AEM, and SOE Electrolyzer Technologies

Modern hydrogen production relies on four primary technologies:

- Proton Exchange Membrane (PEM) excels in dynamic operation, ideal for integrating with renewables

- Alkaline Electrolyzers (AEL) use mature, low-cost designs but perform poorly under variable loads

- Anion Exchange Membrane (AEM) combines moderate efficiency (50–65% in lab settings) with reduced material costs

- Solid Oxide Electrolyzers (SOE) reach 70–90% efficiency at high temperatures but face durability challenges

Recent advancements have reduced PEM degradation to an average of 3% annually, while SOE systems remain limited by thermal stability requirements.

Scalability of Alkaline (AWE) vs Proton Exchange Membrane (PEM) Systems

Alkaline systems dominate small-scale applications due to lower capital costs ($1,816/kW–40% below PEM)–but typically cap out at 10 MW. PEM electrolyzers scale efficiently beyond 100 MW despite higher initial investment ($2,147/kW). A 2024 industry analysis highlights key differences:

| Metric | Alkaline (AWE) | PEM |

|---|---|---|

| Scalability threshold | ≤ 10 MW | ≥100 MW |

| Response time | 5–15 minutes | <1 second |

| Current density | 0.3–0.5 A/cm² | 2.0–3.0 A/cm² |

PEM’s higher current density enables a 40% smaller footprint per kg-H₂ output, a critical advantage for urban or space-constrained renewable projects.

Technology Fit for Different Deployment Scales and Operational Models

Industrial facilities operating at megawatt scale are turning to PEM technology because it maintains around 65 to 75 percent efficiency even when loads fluctuate, whereas alkaline systems still dominate most ammonia production plants below five megawatts capacity. The newer decentralized setups often incorporate modular AEM units specifically designed for hydrogen refueling stations in remote areas, these installations typically run smoothly about 90 percent of the time and require roughly 25 percent less maintenance work compared to traditional options. When it comes to tough conditions such as those found on offshore oil rigs, many operators find that PEM's superior resistance to corrosion makes sense despite paying anywhere from 15 to 20 percent extra upfront compared to standard alkaline solutions available on the market today.

Applications in Centralized vs Distributed Hydrogen Production

Large-Scale Electrolyzers in Centralized Plants and Renewable Energy Storage

In centralized hydrogen production, big electrolyzer units (usually either alkaline or PEM types) help reach better economies of scale when everything runs smoothly, often hitting efficiency rates over 65%. What makes these systems so valuable is their ability to work hand in hand with wind and solar installations. When there's extra renewable energy coming in from those sources, instead of letting it go to waste, these setups convert the surplus into hydrogen storage. The process typically requires less than 4.5 kWh per cubic meter of hydrogen produced. Looking at what's happening on the ground right now, many new projects are installing massive 200 megawatt plus alkaline electrolyzers near offshore wind farms. These locations provide the stable power supply needed to keep operations running nonstop without interruption.

Case Study: Gigawatt-Scale Green Hydrogen Projects Using Alkaline and PEM

An innovative project in the North Sea is combining 1.2 gigawatts worth of alkaline electrolyzers that operate at around 72% lower heating value efficiency with PEM backup systems at about 65% LHV. This mixed approach helps deal with the unpredictable nature of power grids. What makes this setup work so well is that it manages to hit roughly 90% capacity utilization, which translates into making about 220,000 tons of hydrogen each year specifically for creating ammonia. Looking at the economics, alkaline technology clearly has the edge when it comes to running continuously, costing around $450 per kilowatt upfront. Meanwhile, those PEM units are great for quickly adjusting output within seconds to match sudden changes in wind power availability, which is exactly what we need in today's renewable energy landscape.

Small-Scale Electrolyzers for On-Site, Remote, and Niche Industrial Use

Distributed systems (10–500 kW) are viable where transport costs exceed $3/kg. Key applications include:

| Use Case | Technology | Key Benefit |

|---|---|---|

| Mining operations | Containerized PEM | 30-minute deployment time |

| Telecom towers | AEM (Anion Exchange Membrane) | <5% efficiency loss at 40°C |

| Refueling stations | Modular alkaline | 98% purity without additional compression |

These deployments cut logistics costs by 38% compared to centralized supply chains in remote regions.

Modular PEM and AEM Units in Off-Grid and Distributed Energy Systems

Containerized PEM systems now last 1,500 hours in desert climates thanks to advanced humidity control, while AEM electrolyzers (55–60% efficiency) support ammonia synthesis in agricultural areas using sub-100 kW solar arrays. A 2024 field test found modular units reduce hydrogen levelized cost by 22% in microgrids through dynamic matching with renewable generation.

Performance, Efficiency, and Operational Trade-offs by Scale

Efficiency comparison of large vs small electrolyzers under real-world conditions

When it comes to big electrolyzer systems over 5 megawatts, they generally run around 70 to 75 percent efficient when working nonstop. Smaller models under 1 megawatt tend to lag behind at about 60 to 68 percent because they lose more heat during operation. Interesting thing though, modular alkaline setups actually beat their PEM counterparts by roughly 5 to 8 percentage points when dealing with fluctuating renewable energy sources. Looking at actual field results, factories running round the clock prefer those large alkaline systems which hit an average efficiency of 73 percent. Meanwhile, those compact PEM units keep going strong at 65 to 69 percent efficiency even when powered intermittently by solar panels throughout the day.

Impact of continuous operation on durability and system performance

Continuous operation accelerates degradation in PEM electrolyzers by 0.8–1.2% per 1,000 hours, compared to 0.3–0.5% in alkaline systems under stop-start cycling. Large installations mitigate this with advanced thermal management, limiting efficiency loss to under 2% over 15,000 hours. In contrast, small-scale PEM units often require membrane replacement every 3–5 years, increasing total ownership costs by 12–18%.

Debunking the myth: Do larger electrolyzers always deliver better efficiency?

Looking at data from 142 installations around the world shows something interesting about electrolyzer performance. Systems under 500 kW actually perform better than larger ones by around 4 to 7 percent when they run below 40% capacity. This goes against what many people believe - that bigger equipment is automatically more efficient. When systems match real-world demand instead of being oversized, they work best. The latest modular AEM electrolyzers hit about 72% efficiency at 200 kW scale, which matches what we see in traditional industrial alkaline plants. These findings suggest that smaller solutions aren't just viable but technically mature enough for serious applications these days.

Cost Analysis and Economic Viability Across Scales

Capital Expenditures (CapEx) and Cost per kg of Hydrogen: Small vs Large Systems

Big electrolyzer systems over 50 MW actually cost about 35 to 40 percent less per kilowatt than their smaller counterparts under 5 MW. This price difference comes mainly from buying materials in bulk and having standardized production processes. Looking at numbers from the National Renewable Energy Laboratory in 2023, large alkaline electrolyzers can make hydrogen for around $3.10 per kilogram. That's quite a bit cheaper than the $6.80 per kg mark for those containerized PEM units. On the flip side though, smaller systems don't require expensive pipeline networks which makes them pretty good value for things like local hydrogen filling stations where space is limited and distribution isn't feasible.

Durability, Maintenance Costs, and Total Cost of Ownership by Scale

Alkaline electrolyzers used in industry can run for around 80,000 hours before their efficiency drops by just under 0.2% each year. Small PEM units aren't so lucky though they usually need new catalysts after about 45,000 operating hours. The maintenance burden falls much harder on these distributed systems too. Field service alone adds anywhere from 40 cents to 90 cents per kilogram of hydrogen produced compared to less than 15 cents for bigger central plants. Fortunately, newer modular designs are changing things. These allow technicians to replace only parts of the system stacks instead of whole units, cutting down downtime for smaller operations by roughly two thirds according to recent field tests.

Economies of Scale vs Deployment Flexibility in Distributed Networks

Big centralized projects at the gigawatt scale can cut hydrogen production costs by around 18 to maybe even 22 percent compared to smaller operations. But these massive installations need serious capital investment first, typically somewhere between 180 million and 450 million dollars upfront. On the flip side, smaller distributed networks ranging from 5 to 20 megawatts offer different advantages. They give up a bit on cost savings but make up for it with quicker installation times and the ability to place them right next to wind farms or solar arrays where the power is generated. Industry observers are starting to see hybrid systems gain traction too. These mix traditional large alkaline electrolyzers handling about three quarters of the workload with newer PEM or AEM technology modules covering the remaining quarter. The combination seems to strike a good middle ground between keeping costs down while still maintaining flexibility when market conditions change.

FAQ

What factors should be considered when choosing an electrolyzer system? When choosing an electrolyzer system, consider the size, efficiency, scalability, cost, and the specific application (centralized or distributed). Different technologies suit different needs, such as PEM for dynamic operation and renewables and alkaline for large-scale centralized production.

What is the primary advantage of modular electrolyzer systems? Modular electrolyzer systems provide flexibility. They can scale up or down in increments, allowing adjustments to production capacity based on demand, which is ideal for sectors with seasonal variations.

How do operating conditions affect electrolyzer efficiency? Operating conditions can significantly impact efficiency. For instance, PEM systems maintain high efficiency even with fluctuating loads, while alkaline systems see more degradation over time but offer cost savings in materials.

What are common challenges in scaling up electrolyzer technologies? The challenges in scaling up include maintaining efficiency, dealing with expensive catalysts in PEM systems, managing high temperatures in SOE units, and finding the right balance between capital investments and operational flexibility.