How Hydrogen Energy Is Used in Electricity Production

Electricity generation using hydrogen happens mainly through two methods: fuel cells and combustion turbines that have been adapted for hydrogen use. Fuel cell technology works by creating power through electrochemical processes, and when paired with heat recovery systems, these can reach around 60% efficiency rates. Many existing combustion turbines originally built for natural gas operations can now handle hydrogen mixtures or even pure hydrogen, which gives grid operators much needed flexibility for maintaining stable power supply. Green hydrogen production involves splitting water molecules using renewable energy sources such as wind and solar power through a process called electrolysis. This green hydrogen gets stored until there's a dip in renewable energy availability, at which point it can be converted back into electricity. Take Germany for instance, where several offshore wind installations are already generating green hydrogen. These projects have managed to cut down dependence on coal plants by approximately 40% in certain test areas, though results vary depending on local conditions and implementation specifics.

Integration of Hydrogen Into Existing Power Grids

Hydrogen helps make power grids cleaner while keeping them stable too. When there's extra renewable energy around, hydrogen stores it away and then releases it back when demand spikes. Take Denmark for instance their pilot projects have found that putting hydrogen into salt caverns cuts down on wasted energy by somewhere between 15 to maybe even 20 percent each year. We're seeing these hybrid setups pop up where solar farms work alongside electrolysis equipment, though getting everything to work together smoothly needs pretty sophisticated energy management since energy flows both ways through the system. Look at what California is doing with their Renewable Hydrogen Backbone project they actually use hydrogen to keep the grid running steady during those intense heat waves that mess up normal operations so much lately.

Case Study: Hydrogen-Powered Plants in Germany and Japan

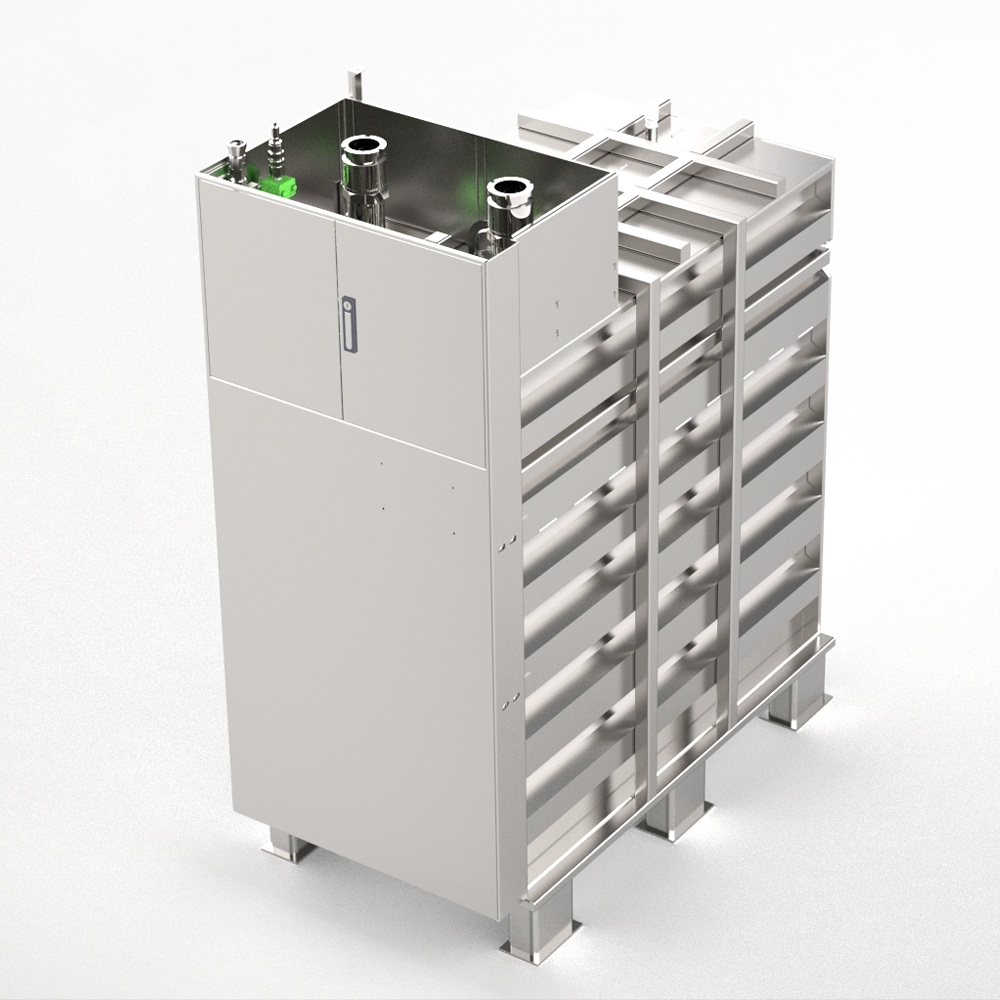

The Energiepark Mainz in Germany combines a 6 megawatt electrolyzer with wind energy sources to generate around 200 tons of hydrogen each year. This setup can actually supply electricity to approximately 2,000 households when there are power cuts through its 1.4 MW fuel cell system. Across the Pacific, Japan has developed something even bigger called the Fukushima Hydrogen Energy Research Field, or FH2R for short. At 10 MW capacity, it stands as the biggest green hydrogen plant globally. Not only does it help power parts of Tokyo, but researchers also use it to experiment with shipping hydrogen across oceans. What makes these projects stand out is their impressive efficiency rate of about 95%. They manage this high performance because they adjust how much hydrogen gets produced based on what the electrical grid actually needs at any given moment.

Challenges in Scaling Hydrogen for Baseload Power

Three major barriers limit hydrogen's role in baseload power:

- Cost: Electrolyzer capital costs remain roughly three times higher than those of natural gas turbines.

- Efficiency losses: The round-trip process of converting electricity to hydrogen and back results in 30–35% energy loss.

- Infrastructure: Less than 15% of global gas pipelines can safely carry hydrogen blends above 20%.

A 2021 industry review highlighted fuel cell durability and pipeline embrittlement as key R&D priorities, estimating $1.2 trillion in infrastructure upgrades needed by 2040. While hydrogen complements renewable energy, it currently lacks cost parity for widespread baseload deployment.

Hydrogen for Heating: Decarbonizing Industrial and Residential Systems

The role of hydrogen energy in decarbonizing heating systems

Around 40 percent of all CO2 emissions from energy consumption worldwide come from heating according to IEA data from last year, which is why many experts see hydrogen as a real game changer for replacing fossil fuels in both industrial furnaces and home boilers. The fact that hydrogen burns at temperatures reaching nearly 2800 degrees Celsius makes it particularly suitable for heavy industries such as steel production. Some tests with fuel cell micro combined heat and power systems showed impressive results too, hitting around 90 percent efficiency when used for district heating networks. What's interesting is that hydrogen actually works pretty well in roughly 20% of current gas pipelines without needing any changes to the infrastructure, something that could really speed up how quickly this technology gets adopted across different sectors.

Blending hydrogen with natural gas in pipelines

Blending hydrogen into existing gas networks offers a transitional pathway:

| Hydrogen Blend | CO2 Reduction | Infrastructure Requirements |

|---|---|---|

| 20% | 7% | Minimal modifications |

| 50% | 18% | Valve/material upgrades |

| 100% | 85–92% | Full system replacement |

European trials show that 20% blends could cut emissions by 6 million tons annually while maintaining safe operation. However, due to hydrogen's lower volumetric energy density, flow rates must increase by 15–25% at higher blend levels.

Pilot projects in the UK and Netherlands using hydrogen for home heating

The HyDeploy program in the UK managed to get hydrogen mixed into the gas supply for around 300 homes at about 20%, and most people seemed happy with it - roughly 8 out of 10 participants reported being satisfied. Over in the Netherlands things got even more interesting with the H2Stad experiment where they actually switched 1,500 homes completely over to hydrogen powered boilers. The results were pretty impressive too since this cut down on heating related emissions by almost 90% when compared against regular natural gas systems. While these test programs show hydrogen can work on a larger scale, there are some concerns worth noting. Tests on materials suggest that if pipelines run full hydrogen all the time, their useful life might shorten somewhere between 12% and maybe 18%. Not great news, but still manageable with proper planning.

Efficiency and safety concerns in hydrogen-based heating

Hydrogen boilers run at around 85 to 90 percent efficiency, which is actually a bit lower than what we see with natural gas at about 94%. The thing about hydrogen though is that it ignites much easier since it only needs 0.02 mJ compared to methane's 0.3 mJ. This means we need really good leak detection systems that can spot even tiny amounts, maybe as little as 1% concentration. According to some recent studies from DNV in 2023, hydrogen tends to seep through polyethylene pipes about 30 times faster than regular gas does. Because of this issue, most older pipe networks will probably need those special composite liners added somewhere along the line. And let's not forget proper ventilation either. When buildings get retrofitted correctly, this simple measure alone can cut down on explosion dangers by nearly 92%.

Hydrogen in Transportation: From Fuel Cells to Aviation

Hydrogen Fuel Cell Vehicles as a Clean Transport Alternative

Fuel cell electric vehicles work by creating power through chemical reactions inside the cell, and they basically just release water vapor as exhaust. The big plus is that filling up takes less than five minutes, and these cars can go well over 500 kilometers before needing another top off. For things like long distance trucks and cargo ships, this makes them better than regular batteries since they pack more energy into smaller spaces without sacrificing too much cargo room. Companies like Toyota and Hyundai have started putting real money behind hydrogen tech for their bigger transport needs lately.

Adoption of Hydrogen Buses and Trucks in California and South Korea

California's H2 Frontier Project has deployed more than 50 hydrogen-powered buses across 12 transit districts since 2023, cutting emissions by 1,200 tons annually. In South Korea, the Ulsan Hydrogen Port operates 120 fuel cell trucks for container transport, supported by nearby offshore wind-powered electrolyzers.

Hydrogen-Powered Trains in Germany and France

Germany's Coradia iLint trains completed 220,000 emissions-free kilometers in 2023. France's TER Occitanie line replaced 15 diesel units with hydrogen hybrid trains, which use roof-mounted fuel cells to extend range on non-electrified routes.

Emerging Applications in Maritime and Aviation Sectors

Maritime operators are using hydrogen-derived ammonia to fuel four cargo ships in the North Sea, reducing CO2 emissions by 85% compared to heavy fuel oil. In aviation, zero-emission regional aircraft powered by liquid hydrogen combustion are expected to enter service by 2035, with current prototypes completing test flights of 750 km.

Infrastructure Challenges for Hydrogen Refueling Networks

Fewer than 1,000 hydrogen refueling stations exist globally, with 42% in Europe and 38% in Asia. High-pressure storage remains expensive—at $1,800 per kg in 2024—and pipeline material brittleness poses challenges for large-scale distribution.

Green Hydrogen Production: Advancing Sustainable Methods

Grey vs. blue vs. green hydrogen: Environmental and economic trade-offs

There are quite a few different ways to produce hydrogen, and they all have their own environmental impact and price tags. Grey hydrogen comes from steam methane reforming (SMR) and releases between 9 and 12 kilograms of CO2 for every kilogram of hydrogen made. The cost? Around $1.50 to $2.80 per kilogram according to the International Energy Agency in 2023. Then there's blue hydrogen which basically takes the same SMR process but adds carbon capture technology. This cuts emissions by about 80 to 90 percent, though it makes things more expensive at roughly $2.50 to $4 per kilogram. And finally we get to green hydrogen, created when electricity from renewable sources powers electrolysis equipment. This method doesn't release any direct emissions and currently runs between $3 and $5 per kilogram. That's actually come down quite a bit from what it used to be just a couple years back when prices were around $4 to $6 per kilogram.

| Type | Feedstock | CO2 Emissions (kg/kg H2) | 2024 Cost Range ($/kg) |

|---|---|---|---|

| Grey | Natural gas | 9–12 | 1.50–2.80 |

| Blue | Gas + CCS | 1–3 | 2.50–4.00 |

| Green | Water + renewables | 0 | 3.00–5.00 |

Electrolysis advancements boosting green hydrogen energy output

Proton exchange membrane (PEM) electrolyzers now reach 75–83% efficiency, up from 60% in 2010. Alkaline systems operate at 65–70% efficiency with lifespans exceeding 60,000 hours. Solid oxide electrolyzers (SOEC), operating at 700–900°C, have achieved 85% efficiency in trials, showing promise for industrial-scale green hydrogen production (ScienceDirect 2024).

Cost trends and scalability of renewable-powered hydrogen production

The cost of producing hydrogen through solar powered electrolysis has fallen dramatically, down around 62% since 2015. We're now seeing prices between $3 and $4.50 per kilogram in 2024. Down under in Australia, wind farms are turning out more than 1,000 tons of green hydrogen each year at about $3.80 per kg. Meanwhile across in China, large scale electrolyzer installations are making production cheaper every year, cutting costs by roughly 18% annually. Looking ahead, BloombergNEF predicts that green hydrogen could hit just $1.50 per kg by 2030. This would happen as renewable energy sources continue their rapid expansion, expected to make up nearly 85% of all new electricity generation worldwide.

FAQ

What are the main methods of generating electricity using hydrogen? The main methods are through fuel cells and combustion turbines adapted for hydrogen.

How does hydrogen contribute to power grid stability? Hydrogen stores excess renewable energy, releasing it during demand spikes to ensure grid stability.

What are some current challenges in using hydrogen for baseload power? High costs, efficiency losses during energy conversion, and infrastructure limitations are major challenges.

How is hydrogen used in heating systems? Hydrogen can replace fossil fuels in industrial and residential heating systems, offering a sustainable alternative.

What advancements have been made in green hydrogen production? Developments in electrolysis technology and large-scale installations have significantly reduced costs and increased efficiency.

Table of Contents

- How Hydrogen Energy Is Used in Electricity Production

- Integration of Hydrogen Into Existing Power Grids

- Case Study: Hydrogen-Powered Plants in Germany and Japan

- Challenges in Scaling Hydrogen for Baseload Power

- Hydrogen for Heating: Decarbonizing Industrial and Residential Systems

- Hydrogen in Transportation: From Fuel Cells to Aviation

- Green Hydrogen Production: Advancing Sustainable Methods

- FAQ