Sustainable Hydrogen as a Clean Energy Carrier

Green Hydrogen Production Through Renewable Energy Integration

Green hydrogen gets made when extra renewable electricity, mostly from wind farms and solar panels, powers something called electrolysis. This basically splits water molecules into hydrogen and oxygen gases while not producing any direct carbon emissions during the process itself. Compared to traditional methods that rely on fossil fuels, this approach cuts down on carbon dioxide emissions significantly – around 9 to 12 kilograms for every kilogram of hydrogen produced conventionally. What makes green hydrogen so promising as a clean energy solution is how it works best when paired with times when there's lots of renewable power available. When electrolyzers run at their peak during these periods, they make better use of resources and actually help reduce stress on the electrical grid rather than adding to it.

Environmental Benefits and Carbon Reduction Potential

Switching over to green hydrogen might cut around 830 million tons of CO2 emissions each year from heavy industries by the mid 2030s according to the International Energy Agency report from last year. The reason? When burned, it produces nothing but water vapor, making it an important tool for reducing carbon footprints across industries including steel production, chemical manufacturing, and shipping operations. If we actually manage to implement this technology on a large scale, industrial areas could see reductions in harmful nitrogen oxide pollution by roughly 45 percent. That kind of improvement would help meet climate targets while at the same time improving air quality for people living near these facilities.

Lifecycle Emissions and Sustainability Criteria for Hydrogen Production

The environmental footprint of hydrogen depends heavily on how it gets made. Studies looking at the full lifecycle reveal that grey hydrogen produced through natural gas reforming releases roughly tenfold more carbon dioxide compared to its green counterpart. The European Union has developed certification standards called RFNBO to verify genuine green hydrogen production. These rules don't just check for renewable energy sources; they actually track when and where electricity was generated versus when electrolysis occurred. Companies need to follow these guidelines carefully. Otherwise, we might end up with hydrogen initiatives that look clean on paper but still prop up our reliance on fossil fuels behind the scenes. This kind of greenwashing could undermine real progress toward sustainable energy solutions.

Role of Green Hydrogen in Supporting Circular Energy Systems

Green hydrogen plays a big role in making circular energy systems work better. When there's extra power from renewables like wind or sun, it gets turned into fuel that can be stored and used later on in various industries or even back into power generation. Some cutting edge plants are now mixing captured CO2 from biological sources with this green hydrogen to make what they call e-methanol, which basically means they're keeping carbon from escaping into the atmosphere. The ability to go both ways is really helpful for balancing out electrical grids where lots of solar panels and wind turbines are connected. Plus, this process creates clean materials needed for things like making fertilizers and steel without all the usual carbon emissions associated with those processes.

Decarbonizing Hard-to-Abate Sectors with Green Hydrogen

Applications in Steel, Chemicals, and Heavy Industry

Green hydrogen offers a way to cut carbon emissions in industrial areas where switching to electricity just doesn't work. Take steel making for instance, which accounts for roughly 7 percent of all CO2 released worldwide. By substituting coal with green hydrogen during the iron ore reduction process, factories can slash their emissions by nearly 98%. The H2 Green Steel project in Sweden has shown this works in practice since 2024. For ammonia production, switching to hydrogen generated through electrolysis cuts emissions down about 40%. Cement producers are finding value too, as mixing hydrogen into their fuel reduces both the heat needed and the amount of dust produced. What makes hydrogen stand out is how it handles extreme temperatures and chemical reactions required in these tough sectors that are difficult to clean up otherwise.

Cross-Sectoral Integration in Industry and Transport

Hydrogen brings together different parts of our energy world in pretty interesting ways. It powers big machines, runs those long distance trucks we see on highways, and helps keep electrical grids stable when demand fluctuates. When there's extra green power from solar or wind sources, we can turn it into hydrogen through this process called electrolysis. Then that hydrogen gets put to work in places like chemical plants where they need intense heat, or even in special trains that run on fuel cells instead of diesel. The real kicker? One single hydrogen pipeline isn't just good for one thing. According to some recent research from 2023, these pipelines could actually meet about a third of an area's industrial heating requirements while also acting as storage solutions during periods when wind farms aren't producing enough power. That kind of dual purpose makes the whole system much more efficient than trying to build separate infrastructure for everything.

Case Study: Green Hydrogen in Steel and Chemical Manufacturing

In Germany, an industrial area managed to slash their Scope 1 emissions by almost two thirds over just 18 months. They did this by switching from natural gas to green hydrogen for processes like steel annealing and making methanol. What makes this even more impressive is that the whole operation runs on power from 140 megawatts worth of offshore wind farms. As a result, they're able to produce around 9,500 tons of hydrogen each year. That amount alone is sufficient for creating approximately half a million tons of steel with much lower carbon content. Looking at how things work together across different industries, this initiative stands out as a great example of shared resources. Nearly all the leftover oxygen and waste heat gets put back into the system somewhere else, with about 92% being reused in some capacity throughout the cluster.

Circularity in the Hydrogen Technology Value Chain

Recycling Critical Materials: Precious Group Metals in Fuel Cells and Electrolysers

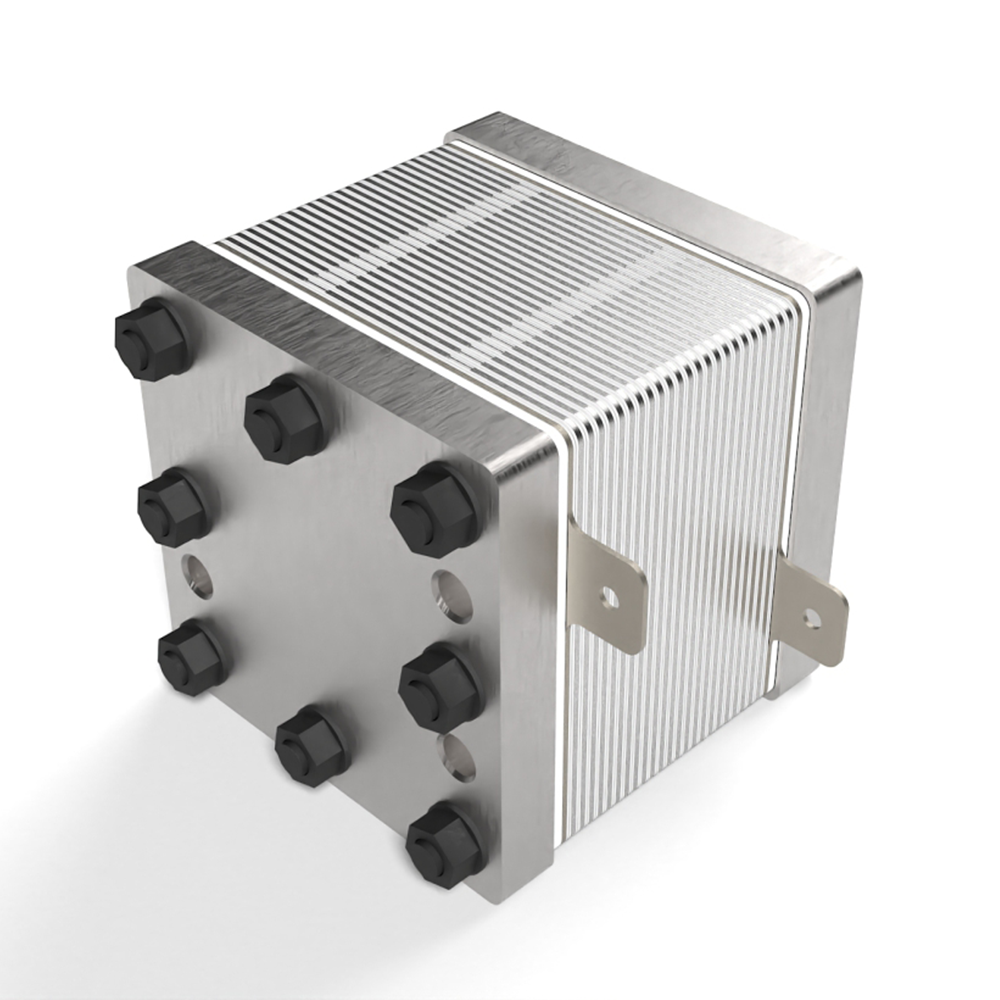

The proton exchange membrane technology relies heavily on platinum group metals like platinum and iridium. These precious metals pose real problems for supply chains because their reserves are limited and their mining processes create significant environmental damage. On the bright side though, when we look at end of life fuel cells and electrolysis units, most of these valuable metals can actually be recovered through recycling efforts. According to recent data from Circular Materials Institute in 2023, recovery rates exceed 90%, which cuts down our dependency on extracting fresh materials from mines. What's even better is that companies working together in closed loop systems with recyclers have managed to slash emissions across product lifecycles by somewhere between forty to sixty percent when compared against traditional methods that rely solely on brand new raw materials.

Design for Reuse and End-of-Life Recovery in Hydrogen Systems

Today's hydrogen systems are moving toward modular setups that actually help prolong the lifespan of equipment by allowing parts to get refurbished or put to new uses. Take electrolyser stacks for instance they often get taken apart and used again in smaller scale operations. Meanwhile those bipolar plates can usually be brought back to life through some kind of electrochemical polishing process. There's also this standard called ISO 22734 from 2023 that's making waves in the industry. It basically helps different pieces work together across various infrastructure generations so older components don't become obsolete when newer tech comes along. This matters because manufacturers want their investments to last longer without having to completely replace everything every few years.

Balancing PGM Mining Impacts with Recycling Rates and Circular Innovation

Recycling helps cut down on the need for fresh PGMs, but we can't ignore that mining still accounts for around 8 to 12 percent of the carbon footprint in hydrogen tech. The International Energy Agency predicts fuel cell manufacturing could triple by 2030, so expanding our recycling capabilities becomes pretty critical. Some interesting options are starting to appear too. We're seeing things like catalysts made from ruthenium and electrolysis systems that don't require precious metals at all. These developments mean less reliance on rare resources and move us closer to those circular economy goals everyone keeps talking about.

Power-to-Gas and Sector Coupling for Integrated Energy Systems

Power-to-gas (P2G) technologies are transforming sustainable energy systems by enabling cross-sector integration and grid flexibility through electrolysis and hydrogen-based storage. These solutions bridge renewable electricity surpluses with industrial energy demands while advancing circular economy principles.

Electrolysis and Methanation: Power-to-Gas Technologies Enabling Flexibility

The process of electrolysis takes renewable electricity and splits water molecules into hydrogen and oxygen gases. Meanwhile, methanation works differently by combining hydrogen with carbon dioxide that has been captured elsewhere to create synthetic methane fuel. These technologies become really interesting when they run on solar panels or wind turbines because then we get fuels that don't release extra carbon into the atmosphere. They work particularly well for industries like aviation where switching entirely to electric power isn't practical yet. Looking at current numbers, modern electrolyzer systems are running around 75 to 80 percent efficient now. That represents about a 15 percentage point jump compared to what was possible back in 2020, which is helping push these technologies closer to becoming commercially viable options for businesses looking to cut emissions.

Hydrogen-Based Energy Storage and Grid Balancing

Hydrogen has an energy density around 33.3 kWh per kilogram which makes it pretty good at storing extra renewable power when demand drops off. When wind farms connect with about 5 gigawatts worth of electrolyzers, they cut down on wasted energy by roughly 34 percent each year in grids where renewables dominate, as shown in research from last year. What this means practically is that power companies can handle those sudden ups and downs in supply better, plus keep electricity flowing even when bad weather hits for days at a time without interruption.

Sector Coupling: Integrating Power, Industry, and Gas Networks

P2G fosters symbiotic relationships across sectors: electricity grids supply hydrogen to fertilizer plants, while industrial waste heat supports district heating. Integrated models show these configurations reduce primary energy waste by 28–32% compared to isolated systems. Hybrid power-gas networks also improve resilience, experiencing 40% fewer outage hours during extreme weather events.

Biomass and Waste-to-Hydrogen Pathways in Circular Carbon Models

Converting Biomass and Organic Waste into Sustainable Hydrogen

Agricultural leftovers, food scraps, and even sewage sludge are getting new life through gasification and anaerobic digestion processes that turn them into hydrogen fuel. Just within Europe, these technologies could handle around 60 million tons of organic waste every year, turning trash into something valuable instead of letting it sit in landfills. Recent improvements in hydrothermal processing methods mean we're getting better results when working with wet biomass materials, so those soggy waste streams that were once problematic can now be processed effectively. The bonus here is environmental protection too since this method stops methane from escaping as waste breaks down naturally over time, which makes sense for anyone concerned about climate change impacts.

Integrating Hydrogen into Circular Carbon Economy Frameworks

Hydrogen made from waste connects natural carbon cycles to efforts to cut industrial emissions. Pairing this approach with carbon capture technology actually results in taking more carbon out of the atmosphere than what gets released. Take landfills for example. Turning their methane emissions into usable hydrogen while locking away CO2 creates what's called a closed carbon loop system. These kinds of setups are particularly helpful for industries like cement manufacturing where they replace traditional fuels in kilns. Plus, the captured CO2 isn't just stored somewhere; it gets put to work growing algae that makes biofuels instead of sitting idle. This keeps carbon molecules actively working in our economy rather than accumulating as pollution.

Comparative Sustainability: Waste-Derived vs. Green Hydrogen

| Factor | Waste-Derived Hydrogen | Green Hydrogen |

|---|---|---|

| Carbon Footprint | -50 to -80 kg CO₂e/GJ¹ | 0–1 kg CO₂e/GJ² |

| Resource Efficiency | Uses existing waste streams | Requires new renewable infrastructure |

| Land Use Impact | Avoids methane emissions from waste | Potential competition with agriculture for solar/wind sites |

Waste-derived hydrogen offers immediate emissions benefits by valorizing waste, while green hydrogen provides a long-term, scalable solution powered by renewable energy.

FAQs about Sustainable Hydrogen

What is green hydrogen and how is it produced?

Green hydrogen is produced through electrolysis powered by renewable energy, such as wind or solar power. This process splits water molecules into hydrogen and oxygen without any direct carbon emissions.

How does green hydrogen reduce carbon emissions?

Green hydrogen allows industries to significantly cut CO2 emissions by substituting fossil fuels with hydrogen, which only emits water vapor when burned.

What are the challenges of using green hydrogen?

The challenges include the need for new renewable infrastructure, certification standards to ensure true green production, and managing supply chains for precious metals used in hydrogen technology.

Can hydrogen truly be sustainable in the long-term?

Yes, particularly if combined with recycling and circular economy efforts to minimize the use of fresh materials and ensure the lifecycle of hydrogen technology components is sustainable.

Table of Contents

- Sustainable Hydrogen as a Clean Energy Carrier

- Decarbonizing Hard-to-Abate Sectors with Green Hydrogen

- Circularity in the Hydrogen Technology Value Chain

- Power-to-Gas and Sector Coupling for Integrated Energy Systems

- Biomass and Waste-to-Hydrogen Pathways in Circular Carbon Models

- FAQs about Sustainable Hydrogen