Fundamentals of Metal Hydride Storage Efficiency and Key Performance Metrics

Defining metal hydride storage efficiency in hydrogen energy systems

The efficiency of metal hydride storage basically tells us how well hydrogen can stick to metal alloys when it gets absorbed and then let go again during release. Compared to just compressing hydrogen gas or keeping it super cold, these metal materials actually store more hydrogen by volume because they trap the hydrogen atoms inside their crystal structures. Recent studies from 2024 showed that most metal hydrides hold between 6 to 10 percent of their weight in hydrogen and can do this back and forth about 95 times before losing effectiveness. That's pretty impressive compared to other methods like activated carbon which only manages around 3 to 5 percent capacity. The ability to cycle through charging and discharging so many times without significant degradation makes metal hydrides especially good for things like fuel cell vehicles or portable power systems where space matters and reliability over time is critical.

Key technical factors influencing hydrogen storage performance

Four critical parameters govern metal hydride system efficiency:

- Material composition (alloy stability and hydrogen affinity)

- Thermal management capacity (±2°C tolerance for optimal reaction kinetics)

- Pressure modulation (1-100 bar operational range)

- Structural porosity (40-60% void fraction for efficient gas diffusion)

Recent studies demonstrate that systems combining magnesium-based alloys with nickel catalysts achieve 23% faster absorption rates than traditional iron-titanium compounds. Thermal regulation proves most vitalevery 10°C temperature fluctuation beyond a hydride's optimal range decreases storage capacity by 8-12% (Li et al. 2023).

Hydrogen absorption and desorption rates as critical performance benchmarks

The T90 metric, which measures how long it takes to reach 90% capacity, has become pretty much standard across the industry when assessing metal hydride systems these days. Some advanced reactor models can actually hit those T90 absorption targets within just three minutes thanks to their helical cooling tubes, which represents about a fourfold improvement compared to what we saw in the earliest versions back in the day. On the flip side though, desorption rates still face serious challenges because of heat constraints. Most commercially available systems take anywhere from fifteen to twenty minutes before they fully release all that stored hydrogen. Looking at recent studies on kinetics optimization, researchers found something interesting: adding copper to hydrides cuts down the activation energy needed by around seventeen percent. This leads to better performance overall, with faster absorption speeds cutting T90 times by approximately twelve percent while also boosting desorption efficiency and increasing hydrogen yields by roughly nine percent.

Thermal Management Challenges and Heat Transfer Solutions in MH Systems

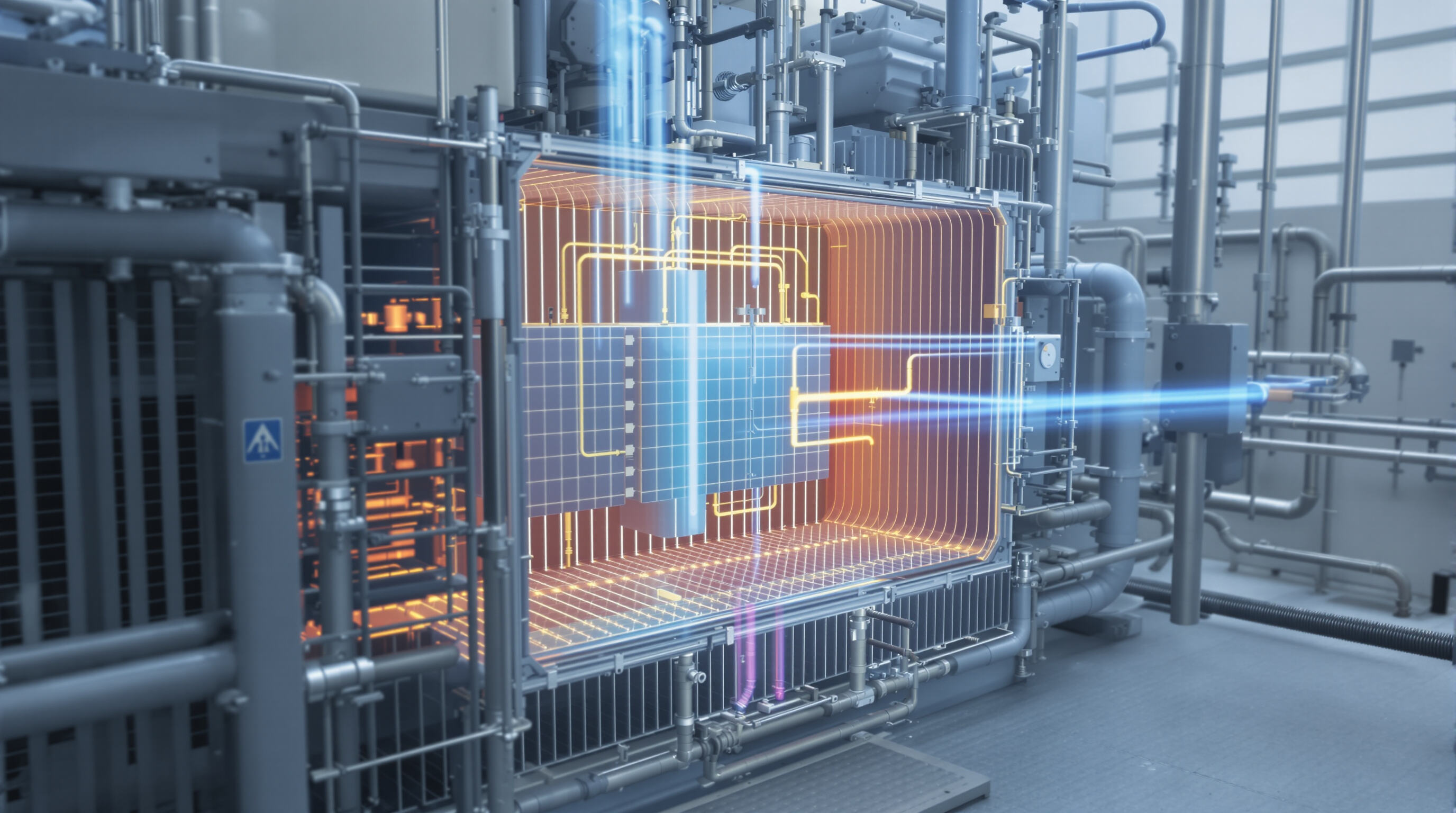

Impact of Exothermic and Endothermic Reactions on Metal Hydride Storage Stability

MH systems run into real problems with heat management because when they absorb hydrogen, it releases heat (exothermic), while releasing hydrogen requires absorbing heat (endothermic). This back and forth creates temperature differences across the material. Recent reactor models from 2023 show these temperature swings can cut down on how much hydrogen gets stored, sometimes by as much as 35% if there's no control over the environment. What's worse, the constant heating and cooling wears out the hydride materials themselves. Systems subjected to this kind of thermal abuse tend to last only 60% to 80% as long as those with proper temperature regulation, which makes a big difference in real world applications where reliability matters most.

Thermal Modeling and Performance Evaluation of Metal Hydride Reactors

Advanced computational models now predict heat distribution patterns within MH reactors with 92% accuracy, enabling optimized fin configurations and cooling tube placements. Experimental validations show helical tube designs improve heat rejection efficiency by 28% over traditional layouts, while radial fin arrays reduce absorption time (t90) by 15 minutes per cycle.

Integration of Phase Change Materials for Enhanced Heat Transfer

Research shows that phase change materials (PCMs), including those made from paraffin wax composites, can soak up around 40% more heat energy per gram compared to regular aluminum heatsinks. Embedding these materials into metal hydride (MH) beds helps keep reaction temps pretty close to what they should be, staying within about plus or minus 5 degrees Celsius of target levels. Keeping things this stable is really important for getting good performance out of metal hydride storage systems when they're going through fast charge-discharge cycles. The PCM method also cuts down on how much extra cooling power we need, saving roughly 60% of that energy cost in medium sized storage units according to tests with prototype systems.

Passive vs. Active Cooling: Evaluating Scalability and Efficiency in Large-Scale MH Storage

| Cooling Method | Energy Efficiency | Scalability | Maintenance Needs |

|---|---|---|---|

| Passive (PCM/fins) | 85-92% | High | Low |

| Active (liquid) | 70-78% | Moderate | High |

Passive systems demonstrate 18% higher cost-effectiveness in stationary applications, while active cooling enables 35% faster hydrogen release ratesa critical factor for automotive fuel cell integrations. Hybrid designs now achieve 95% thermal stability in 100kg+ storage tanks, bridging the scalability gap between laboratory prototypes and industrial deployments.

Reactor and Tank Design Optimization for Improved Storage Efficiency

Helical Tube Configurations and Their Impact on Heat and Mass Transfer

New reactor shapes are changing how well we store metal hydrides by solving those pesky thermal issues. Some recent work shows that when they twist the tubes into helix shapes instead of keeping them straight, the heat transfer gets better by about 18 to maybe even 34 percent. This means hydrogen can be absorbed much quicker than before. A paper from the Journal of Energy Storage back in 2025 found something interesting too. They looked at these double coiled designs and saw they pulled out heat at an impressive rate of around 1,389 kilowatts per kilogram of hydride material. Plus, these designs stay small enough for actual portable applications which is really important. The twisted geometry basically cuts down on those temperature differences across the system that usually stop people from getting all the storage capacity they paid for.

Influence of Coil Dimensions and Cross-Sectional Area on Absorption Time (t90)

Coil optimization directly governs hydrogen charging speeds:

- Outer diameters ¥6 mm reduce coolant pressure drop by 22%

- Pitches ¤20 mm shorten t90 (time to 90% saturation) to 251 seconds at 15 bar

- Cross-sectional symmetry prevents hydrogen "dead zones" in reactors

Smaller inner diameters (4 mm) improve heat transfer surface density by 40%, though excessively narrow tubes risk flow restrictions. Multi-objective algorithms now balance these parameters to cut absorption times without compromising durability.

Optimizing Metal Hydride Tank Design for Higher Gravimetric and Volumetric Efficiency

Advanced reactors achieve unprecedented weight ratios (hydride mass to reactor mass) of 2.39 through:

- Thin-walled alloy shells: Reduce parasitic weight by 33%

- Graded porosity filters: Maximize volumetric density (14.07 kg LaNi per unit)

- Distributed sensors: Enable real-time hydrogen distribution monitoring

These innovations address the historic trade-off between storage capacity and system portability, with prototype reactors showing 277% higher weight ratios than traditional spiral designs.

Improving Hydrogen Charging Kinetics and Cycle Efficiency

Metal hydride storage efficiency hinges on optimizing hydrogen charging speeds while maintaining stable cycling performance. Recent advances demonstrate how targeted thermal integration and system redesign can dramatically accelerate hydrogen absorption without compromising safety.

Reducing hydrogen charging time through thermal integration and system design

New approaches to managing heat have slashed hydrogen charging times by anywhere from 30 to almost 70 percent in the latest prototype designs. When conical heat exchangers work together with those special phase change materials or PCMs for short, they help spread out the heat better during this whole exothermic absorption thing that happens. The PCM jackets basically soak up all that extra heat when charging occurs, then let it go again during discharge periods. This setup takes some pressure off the metal hydride matrix, which keeps reactions stable without getting too hot under the collar.

Accelerating storage cycles with enhanced reaction kinetics

Optimizing hydrogen inlet pressure and heat transfer fluid parameters accelerates reaction kinetics by 18%, enabling full charge/discharge cycles in 7,000 seconds versus 12,100 seconds in conventional systems. Computational models reveal that increasing Reynolds numbers in cooling channels enhances heat dissipation, allowing faster cycling without exceeding temperature thresholds.

Balancing energy efficiency, speed, and safety in repeated hydrogen cycling

Advanced PCM configurations achieve 93% energy recovery during hydrogen release while keeping peak operating temperatures below 85°C. Sensitivity analyses identify optimal pressure (15-20 bar) and coolant flow rates (0.5-1.2 m/s) that prevent hydride degradation across 5,000+ cyclesa critical balance for commercial viability.

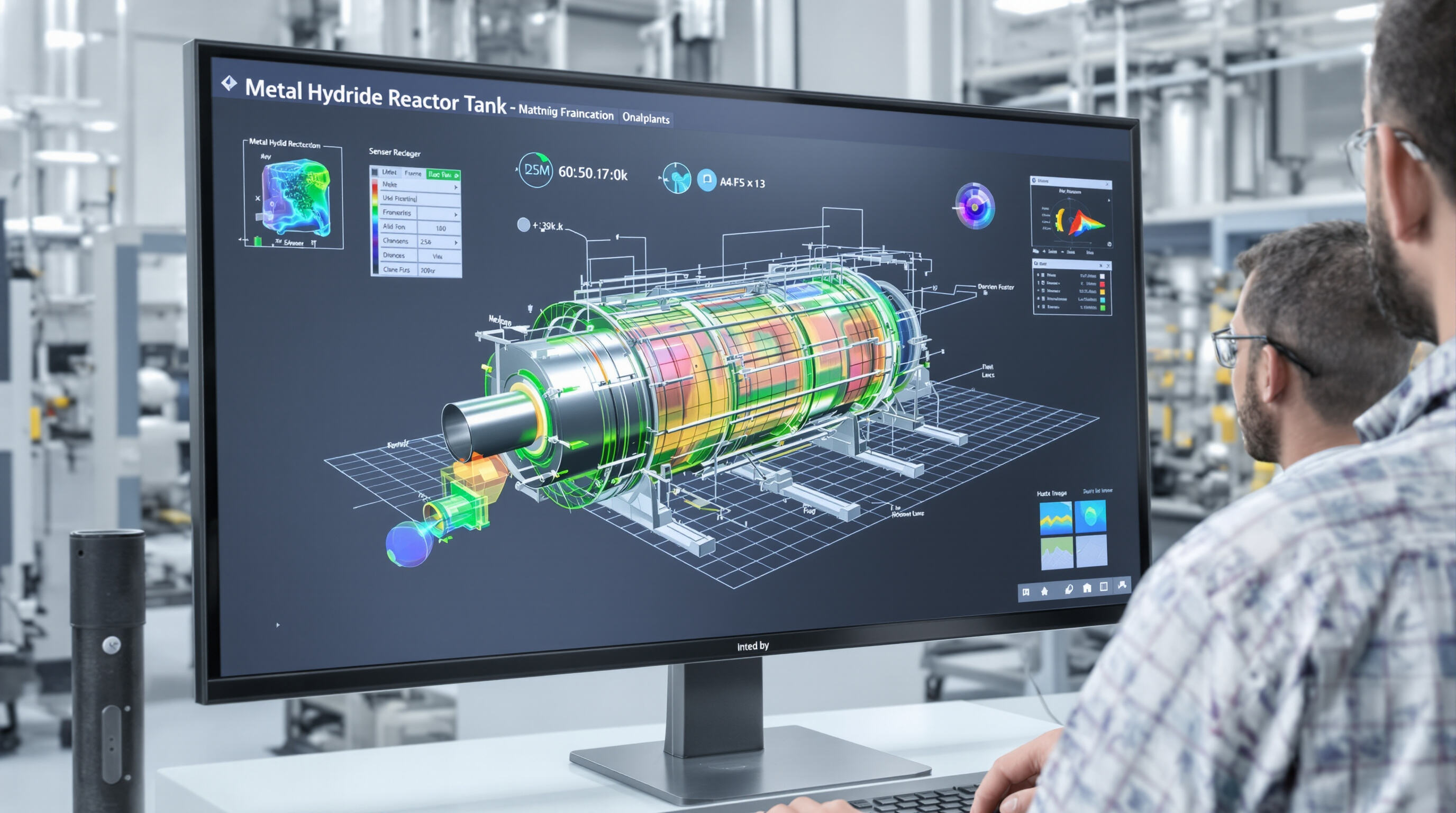

Advanced Modeling and Digital Tools for Predicting and Enhancing MH Efficiency

Machine Learning for Predicting Hydrogen Absorption Time in Storage Canisters

Recent advances in machine learning have brought prediction accuracy down to around 8% or less when it comes to forecasting how long hydrogen takes to be absorbed by metal hydride systems. These algorithms look at about fourteen different factors during operation, such as changes in pressure from 5 to 100 bar and temperature ranges between 20 and 120 degrees Celsius. What this means is that researchers don't need to run nearly as many tests anymore, saving them roughly forty percent of their usual validation time. The deep learning models actually work with live sensor readings to fine tune the absorption process itself. This has resulted in significant improvements where systems reach 90% capacity much faster than before, sometimes cutting the time needed by almost a third compared with older fixed operating methods.

Simulation-Driven Optimization of Metal Hydride Storage Systems

Multi-physics simulations reveal helical tank geometries improve heat distribution by 28% versus conventional designs. A 2024 parametric study shows:

| Design Parameter | Efficiency Gain | Cycle Life Improvement |

|---|---|---|

| Helical tube pitch (158 mm) | +19% thermal transfer | +200 cycles |

| Wall thickness (31.5 mm) | +12% Hâ density | -15% mechanical stability |

These tools enable engineers to balance gravimetric capacity (6.5 wt%) against system durability (¥10,000 cycles).

Digital Twins and Real-Time Monitoring for Dynamic Reactor Performance Evaluation

The latest improvements in how we apply digital twins to industrial setups have shown pretty impressive results when it comes to forecasting problems with metal hydride reactors. Some tests actually hit around 92% accuracy rate in spotting these degradation patterns before they become serious issues. When plant managers start linking real time IoT sensors with those detailed 3D thermal models, they're seeing about an 18% speed boost in responding to changes in system capacity. Take last year's test run at one facility where they implemented cloud based monitoring solutions. What happened? The amount of hydrogen lost during normal operation cycles dropped dramatically from nearly 9.2% down to just over 4.1% across their 300 plus kilowatt hour storage units. That kind of improvement makes a big difference in operational efficiency.

FAQ

What is metal hydride storage, and why is it important?

Metal hydride storage involves using metal alloys to absorb and release hydrogen gas, which is important because it allows for more efficient and compact hydrogen storage compared to traditional methods like high-pressure gas storage or cryogenic liquid storage.

How does thermal management affect metal hydride storage?

Thermal management is crucial in metal hydride storage as it ensures that the system maintains the correct temperature for optimal hydrogen absorption and desorption. Poor thermal management can lead to decreased storage capacity and faster material degradation.

What advancements have been made in metal hydride storage efficiency?

Recent advancements in metal hydride storage efficiency include the use of phase change materials, helical tube designs, and machine learning algorithms that have collectively improved hydrogen absorption times, enhanced thermal management, and provided better prediction and monitoring capabilities.

Table of Contents

- Fundamentals of Metal Hydride Storage Efficiency and Key Performance Metrics

-

Thermal Management Challenges and Heat Transfer Solutions in MH Systems

- Impact of Exothermic and Endothermic Reactions on Metal Hydride Storage Stability

- Thermal Modeling and Performance Evaluation of Metal Hydride Reactors

- Integration of Phase Change Materials for Enhanced Heat Transfer

- Passive vs. Active Cooling: Evaluating Scalability and Efficiency in Large-Scale MH Storage

- Reactor and Tank Design Optimization for Improved Storage Efficiency

- Improving Hydrogen Charging Kinetics and Cycle Efficiency

- Advanced Modeling and Digital Tools for Predicting and Enhancing MH Efficiency

- FAQ